Dossier Océan et énergie - Énergie Thermique des Mers

Sommaire IOA News Letters

Ocean Thermal Energy

Conversion(OTEC)III

by

L. A. Vega. Ph. D.,

Hawaii, USA

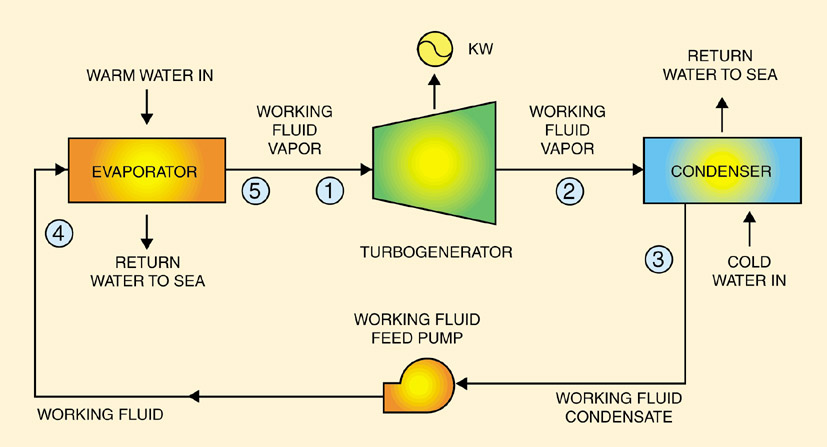

8) Closed Cycle OTEC

The operation of a closed-cycle OTEC plant, using anhydrous ammonia as the working fluid, is modeled with the saturated Rankine cycle. Figure 3 shows a simplified flow diagram of the CC-OTEC cycle. The analysis of the cycle is straightforward. Based on a unit mass flow rate of ammonia vapor (kg s-1) in the saturated cycle:

Heat added (J/Kg) : qA=h1-h4

Turbine work (J/Kg) : WT=h1-h2

Heat Rejected (J/Kg) : |qR|=h2-h3

Pump work (JKg) : |Wp=h4-h3

Cycle net work (J/Kg) : ¡µWnet=( h1-h2 )-(h4-h3 )

Thermal efficiency : £bth=Wnet /qA=( h1-h2 )-( h4-h3 ) /( h1-h4 )

where, h is the enthalpy at the indicated state point. It follows that the heat-added plus the pump-work is equal to the heat-rejected plus the turbine-work.

Figure3. Closed-Cycle OTEC Flow Diagram

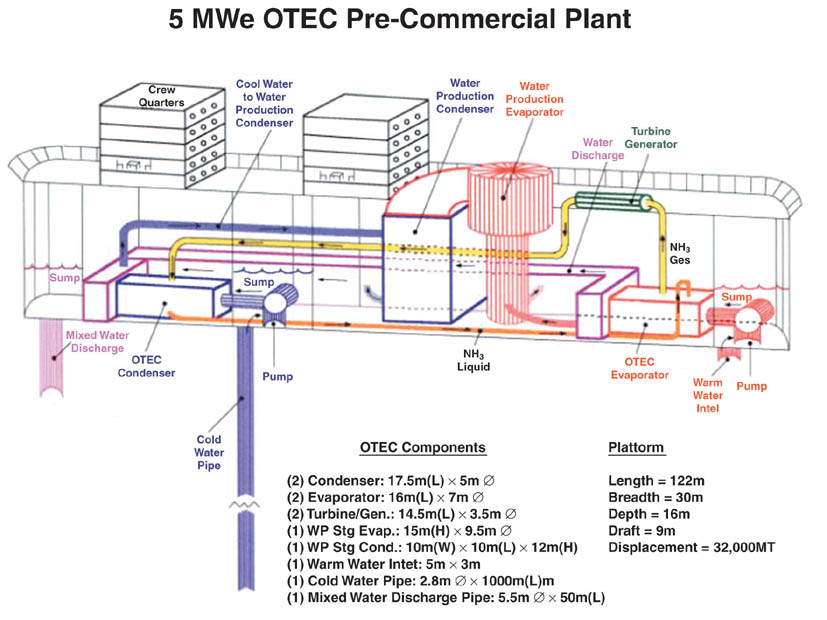

9) Design of a Pre-Commercial Floating Hybrid-OTEC Plant

To understand the details of the design and operation of a CC-OTEC plant, it is useful to consider a specific example given by the 5 MW (nominal) floating hybrid-OTEC. The author conceived this plant, as the pre-commercial plant needed to demonstrate the technical and economical viability of OTEC and to assess the environmental impact. Unfortunately, funding was not secured.

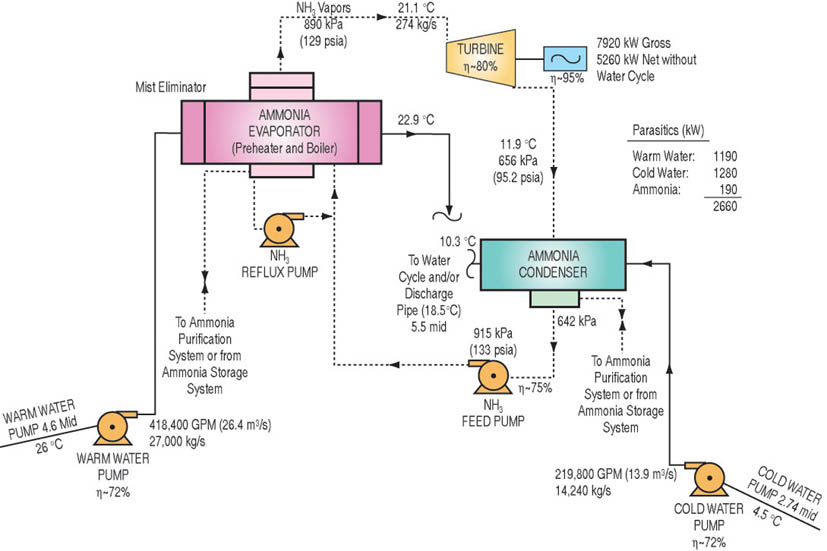

A simplified flow diagram of the power cycle is shown in Figure 4. The plant is based on a closed-cycle for electricity production and on a second stage, using the effluent water streams from the power cycle, for desalinated water production. The baseline is for a floating plant, i.e., the power and water cycles are housed in a barge or ship with the electricity transmitted to shore via a 15 cm submarine power cable and the desalinated water via a small, 15 to 16 cm diameter hose pipe.

Assuming temperatures of 26 ¢XC and 4.5 ¢XC for the surface and deep ocean waters, in the electricity production mode, a gross power output of 7920 kW, using off-the-shelf technology, is sufficient to produce 5260 kW-net with an in-plant consumption of 2660 kW. The power output for this cycle varies as a function of surface water temperature (the cold water temperature is essentially constant) by 860 kW per ¢XC. For example, for 28 ¢XC temperature (average summer conditions in Hawaii) the output would be 6980 kW-net. With the combined production of desalinated water and electricity, the baseline outputs would be 5100 kW-net (160 kW required for the second stage plant) and a daily production of 2281 m3 of desalinated water. This water output is only 20 percent of the amount that can be produced with the second stage.

The proposed baseline facility will employ pressurized ammonia as the working fluid in the power cycle. The baseline seawater flow rates are: 26.4 m3 per day of warm water and 13.9 m3 per day of cold water. These flow rates can be supplied using validated technologies. A 2.74 m (inside diameter) glass fiber reinforced plastic (FRP) cold water pipe will be suspended from the barge to a depth of 1000 m.

Warm seawater will be drawn in through a 4.6 m FRP pipe from a depth of 20 m. The mixed effluent will be discharged through a 5.5 m FRP pipe at a depth of 60 m. This discharge depth has been selected to minimize the environmental impact. The baseline design employs compact heat exchangers for the evaporator and condenser. A chlorinating unit will be installed to minimize biofouling of the evaporator passages. It is known that biofouling from cold seawater is negligible and that evaporator fouling can be controlled effectively by intermittent chlorinating (50-100 parts per billion chlorine for 1 hour every day). Monitoring of the effluent water for elevated concentrations of ammonia or chlorine will be performed on a regular basis.

The seawater effluents from the power cycle exhibit a temperature difference of 12 ¢XC. This residual thermal gradient could not be used in an additional power stage, but it allows the production of significant amounts of desalinated water through a Desalinated Water Cycle (DWC)

or second stage water production. The DWC is an OC-OTEC cycle without the turbine. In a low-pressure vessel, or evaporator, the warm seawater is partially flashed into steam. The evaporator is connected to two surface condensers, where the steam is converted into desalinated (fresh) water by exchanging heat with the cold seawater. During this process, dissolved gases, mainly nitrogen and oxygen, are released from the warm seawater when pressures as low as 2 percent of an atmosphere are reached. These non-condensable gases must be evacuated continuously from the second condenser, or vent condenser, by a vacuum compressor to prevent accumulation and sustain the required low operating pressures. Non-condensables also adversely affect condensation performance through a blanketing effect at the heat exchanger walls. To reduce the impact of released non-condensable gases, a pre-deaeration chamber at about 17 kPa is installed below the flashing chamber, so that much outgassing occurs before steam generation, and at a higher pressure more suitable for compression. Moreover, gases are discharged into the warm seawater effluent at subatmospheric pressures of about 30 kPa, a procedure that not only saves power, but also restores the gas content of the warm seawater before it returns to the ocean.

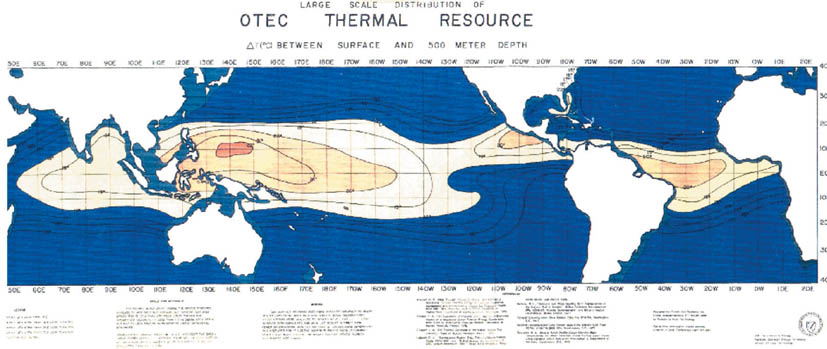

10) Potential Sites

The following summarizes the availability of the OTEC thermal resource throughout the world:

(1) Equatorial waters, defined as lying between 10 ¢XN and 10 ¢XS are adequate except for the West Coast of South America; significant seasonal temperature enhancement (e.g., with solar ponds) would be required on the West Coast of Southern Africa; moreover, deep water temperature is warmer by about 2 ¢XC along the East Coast of Africa. (2) Tropical waters, defined as extending from the equatorial region boundary to, respectively, 20 ¢XN and 20 ¢XS, are adequate, except for the West Coasts of South America and of Southern Africa; moreover, seasonal upwelling phenomena would require significant temperature enhancement for the West Coast of Northern Africa, the Horn of Africa, and off the Arabian Peninsula. The physical factors affecting OTEC site selection, i.e., thermal resource and seafloor bathymetry, greatly restrict the number of desirable sites along the shoreline of major continents, unless some warm seawater temperature enhancement is possible. The best, land-based, OTEC sites consist of island locations. The severe constraint of a favorable bathymetric profile, for the practical implementation of land-based OTEC technologies, would be relaxed to a considerable extent with floating OTEC plants. The potential benefits of OTEC could only be recovered on a large scale through the development of an ambitious floating-plant program, following the initial experimental land-based OTEC phase.

Many other points must be considered when evaluating potential OTEC sites, from logistics to socioeconomic and political factors. One argument in favor of OTEC lies in its renewable character ¡V it may be seen as the means to provide remote and isolated communities with some degree of energy independence, and to offer them a potential for safe economic development. Paradoxically, such advantages are often accompanied by serious logistical problems during the plant construction and installation phases. If an island is under development, it is likely to lack the infrastructure desirable for this type of project, including harbors, airports, good roads and communication systems. Moreover, the population base should be compatible with the OTEC plant size ¡V adequate personnel must be supplied to operate the plant, and the electricity and desalinated water plant outputs should match local consumption in orders of magnitude. 1 to 10 MW plants would generally suffice in most small Pacific islands, whereas in the case of populous and industrialized countries several of the largest feasible OTEC plants, up to 100 MW, could be considered.

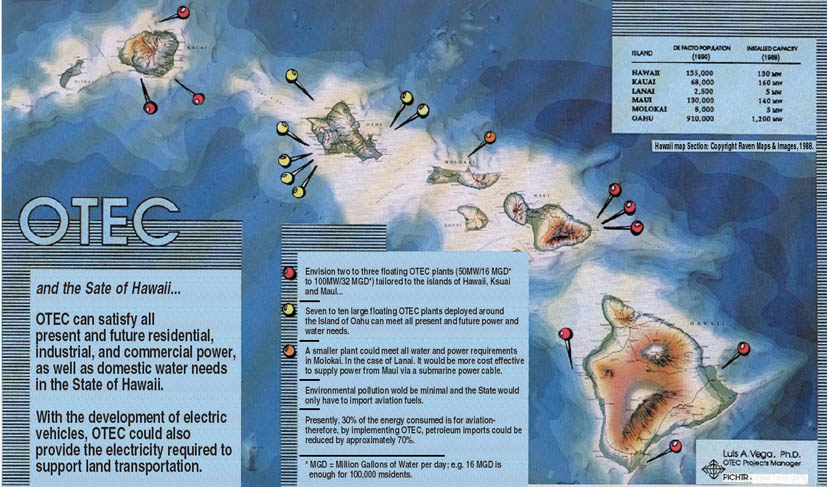

There are at least two distinct markets for OTEC: (i) industrialized nations and islands; and, (ii) smaller or less industrialized islands with modest needs for power and desalinated water. Small OC-OTEC plants can be sized to produce from 1 MW to 10 MW of electricity, and at least 1700 m3 to 3500 m3 of desalinated water per day. That is, the needs of developing communities with populations ranging from 4500 to as much as 100 000 could be met. This range encompasses the majority of less developed island nations throughout the world. Larger CC-OTEC or hybrid cycle plants can be used in either market for producing electricity and water. For example, a 50 MW hybrid cycle plant producing as much as 62 000 m3 of water per day could be tailored to support a developing community of approximately 300 000 people or as many as 100 000 people in an industrialized nation.

A study performed for the US Department of State in 1981, identified ninety-eight nations and territories with access to the OTEC thermal resource (20 ¢XC temperature difference between surface water and deep ocean water) within their 200 nautical miles EEZ, exclusive economic zone. For the majority of these locations, the OTEC resource is applicable only to floating plants. A significant market potential of up to 577 000 MW (equivalent to 6 percent of present day power consumption by humanity) of new baseload electric power facilities was postulated. In view of the discussion given above, this volume of power production will represent an environmental impact of significant proportion, primarily due to the movement of massive amounts of seawater. Unfortunately, now as in 1981, there is no commercial size OTEC plant with an operational record available. This still remains an impediment to OTEC development.

11) Economic Considerations and Market Potential

In considering the economics of OTEC, it is appropriate to determine if multiple-product systems, e.g., electricity, desalinated water, mariculture, and air conditioning (AC) systems yield higher value by, for example, decreasing the equivalent cost of electricity. Because mariculture operations, as in the case of AC systems, can only use a relatively minute amount of the seawater required for the thermal plants they should be evaluated independent of OTEC. For example, the cold water available from a 1 MW OTEC plant could be used for daily exchanges of twenty-five 100 m x 100 m ¡@ example, the cold water available from a 1 MW OTEC plant could be used for daily exchanges of twenty-five 100 m x 100 m x¡@ 1 m mariculture ponds, requiring more than 25 Ha of land. Therefore, it is recommended that OTEC be considered for its potential impt in the production of electricity and desalinated water and that mariculture and AC systems, based in the use of deep ocean water, be considered decoupled from OTEC.

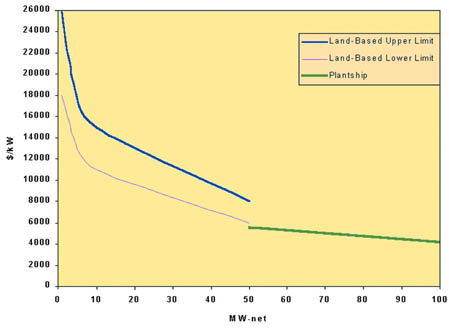

OTEC is capital-intensive (see Figure 5), and the very first plants will most probably be small requiring a substantial capital investment. Given the relatively low cost of crude oil, and of fossil fuels in general, the development of OTEC technologies is likely to be promoted by government agencies rather than by private industry. The motivation of governments in subsidizing OTEC may vary greatly, from foreign aid to domestic concerns. For the former case, ideal recipient countries are likely to be independent developing nations. If their economic standing is too low, however, the installation of an OTEC plant, rather than direct aid in the form of money and goods, may be perceived as inadequate help. In addition, political instability could jeopardize the good will of helping nations to invest. For the latter case, potential sites belong to, or fall within the jurisdiction of, developed countries.

Figuer5. Capital Cost Estimates for Single-Stage OTEC Plants.

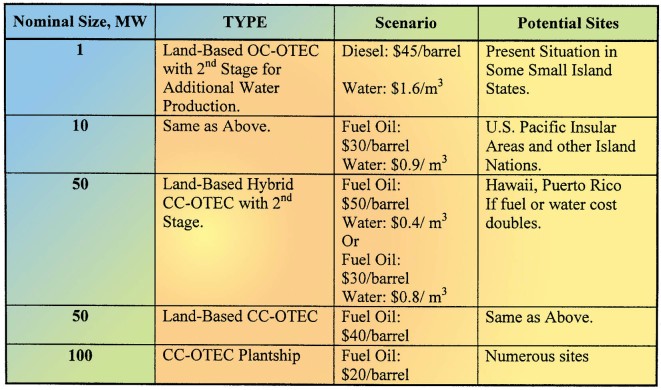

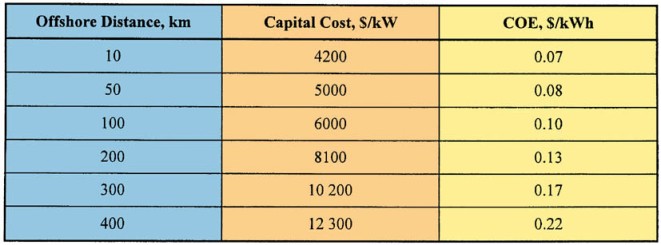

Comparing production costs of electricity and desalinated water can identify scenarios under which OTEC should be economical, relative to conventional technologies. Table 1 summarizes results obtained for the capital costs given in Figure 5 using a fixed rate of 10 percent, 20 year loan, and OTEC plant availability of only 80 percent. Operation and maintenance costs corresponding to approximately 1.5 percent of the capital cost are used. One scenario corresponds to small island nations, where the cost of diesel-generated electricity and fresh water is such that a small, 1 MW land-based OC- OTEC plant, with water production, would be cost-effective today. However, only a few sites throughout the world meet this scenario. A second scenario corresponds to conditions that are plausible in several island nations where 10 MW land-based OC-OTEC plants could produce cost competitive electricity and desalinated water. One can envision these small plants deployed in, for example, Pacific islands such that 20 years from now a total of 100 to 300 MW would be installed. A third scenario corresponds to land-based hybrid OTEC plants for the industrialized nations market producing electricity through an ammonia cycle and desalinated water through a flash (vacuum) evaporator. This scenario would be cost-effective in industrialized island nations with a doubling of the cost of oil fuel or with a doubling of water costs, and for plants rated at 50 MW or larger. The fourth scenario is for floating OTEC electrical plants, rated at 100 MW or larger, and housing a factory or transmitting electricity to shore via a submarine power cable. These plants could be deployed throughout the EEZ of numerous nations and could encompass a significant market. Estimates of their capital costs and resulting costs of electricity are given in Table 2.

Table1. OTEC Potential Sites as a function of Fuel and Water Cost.

Table2. Cost Estimates for 100 MW CC-OTEC Plantship (COE for 10% Fixed Rate, 20 years, Annual o&M 1% percent of Capital Cost)

12) Hydrogen Production

Several means of energy transport and delivery from plants deployed throughout the tropical oceans have been considered. OTEC energy could be transported via electrical, chemical, thermal and electrochemical carriers. The technical evaluation of non-electrical carriers leads to the consideration of hydrogen produced using electricity and desalinated water generated with OTEC technology. The product would be transported, from the OTEC plantship located at distances of 1,600 km (selected to represent the nominal distance from the tropical oceans to major industrialized centers throughout the world) to the port facility in liquid form to be primarily used as a transportation fuel. A 100 MW-net plantship can be configured to yield (by electrolysis) 1300 kg per hour of liquid hydrogen. Unfortunately, the production cost of liquid hydrogen delivered to the harbor would be equivalent to a $250 barrel-of-crude-oil (approximately 10 times present cost). The situation is similar for the other energy carriers considered in the literature. Presently, the only energy carrier that is cost-effective for OTEC energy is the submarine power cable. This situation might be different if the external costs of energy production and consumption are accounted for.

13) Externalities

At present, the external costs of energy production and consumption are not considered in determining the charges to the user. Considering all stages of generation, from initial fuel extraction to plant decommissioning, it has been determined that no energy technology is completely environmentally benign. The additional costs associated with corrosion, health impacts, crop losses, radioactive waste, military expenditures, employment loss subsidies (tax credits and research funding for present technologies) have been estimated to range from 78 to 259 billion dollars per year. Excluding costs associated with nuclear power, the range is equivalent to adding from $85 to $327 to a barrel of fuel oil, increasing the present cost by a factor of 4 to 16. As a minimum, consider that the costs incurred by the military, in the USA alone, to safeguard oil supplies from overseas is at least $15 billion corresponding to adding $23 to a barrel of fuel >¡X equivalent to doubling the present cost. Accounting for externalities might eventually help the development and expand the applicability of OTEC, but in the interim the future of OTEC rests in the use of plantships housing closed (or hybrid) cycle plants transmitting the electricity (and desalinated water) to land via submarine power cables (and flexible pipelines).

Conventional power plants pollute the environment more than an OTEC plant would and, as long as the sun heats the oceans, the fuel for OTEC is unlimited and free. However, it is futile to use these arguments to persuade the financial community to invest in a new technology until it has an operational record. The next step in the development of OTEC is the installation and operation of a pre-commercial plant sized such that it can be scaled to 100 MW.

Bibliography

| Claude G. (1930), "Power from the Tropical Seas" in Mechanical Engineering, Vol. 52, No.12, 19, pp. 1039-1044. [The original paper] | |

| Hubbard H.M (1991), ¡§ The Real Cost of Energy ¡¨, Scientific American, April 1991, Vol. 264, No. 4, PP 18-23. [The range of the external costs of energy production are presented] | |

| Nihous G.C. and Vega L.A. (1991), ¡§ A Review of Some Semi-empirical OTEC Effluent Discharge Models ¡¨, in Oceans ¡¥91, Honolulu, Hawaii. [The OTEC effluent models are summarized] | |

| Quinby-Hunt M.S., Sloan D., and Wilde P. (1987), Potential Environmental Impacts of Closed-cycle Ocean Thermal Energy Conversion ¡¨ , in Environ Impact Assess Rev, Elsevier Science Pub. Co., Inc., New York, NY, pp. 169-198. [The environmental impact expected from CC-OTEC systems is discussed] | |

| Quinby-Hunt M.S., Wilde P., and Dengler A.T (1986), ¡§ Potential Environmental Impacts of Open-cycle Ocean Thermal Energy Conversion ¡¨ , in Environ Impact Assess Rev, Elsevier Science Pub. Co., Inc., New York, NY, pp. 77-93. [The environmental impact expected from OC-OTEC systems is discussed] | |

| Syed M.A., Nihous G.C., and Vega L.A. (1991), ¡§Use of Cold Seawater for Air Conditioning ¡¨, OCEANS ¡¥ 91, Honolulu, Hawaii. [The use of cold seawater for air conditioning is proposed] | |

| Sverdrup H.V., Johnson M.W., and Fleming P.H. (1942), The Oceans: Their Physics, Chemistry, and General Biology, Prentice-Hall, New York. [The classical reference for Oceanographers] | |

| Thomas A., and Hillis D. L. (1989), Biofouling and corrosion Research for Marine Heat Exchangers, prepared by Argonne national Laboratory, Energy and Environmental Systems Division for US. Department of Energy, Wind/Ocean Technologies Division. Presented at Oceans ¡¥89 Conference, Seattle, Washington, DC. [The principal reference on biofouling and corrosion of OTEC heat exchangers] | |

| Vega L.A., and Nihous G.C. (1988), ¡§ At-Sea Test of the Structural Response of a Large Diameter Pipe Attached to a Surface Vessel ¡¨, Paper #5798, Offshore Technology Conference, Houston, May 1988. [The proven design for coldwater pipes for OTEC plantships is presented] | |

| Vega L.A. (1995), ¡§ Ocean Thermal Energy Conversion ¡¨, in Encyclopedia of Energy Technology and the Environment, John Wiley & Sons, Inc., New York, NY, pp. 2104-2119. [The main reference updated in this article] | |

| Vega L.A. (1992), ¡§ Economics of Ocean Thermal Energy Conversion (OTEC) ¡¨ in R.J. Seymour, ed. Ocean Energy Recovery: The State of the Art, American Society of Civil Engineers, New York. [The OTEC capital costs and related costs of electricity and water production are presented] | |

| Vega L.A. (1995), ¡§ Ocean Thermal Energy Conversion ¡¨, in Encyclopedia of Energy Technology and the Environment, John Wiley & Sons, Inc., New York, NY, pp. 2104-2119. [The main reference updated in this article] |

The Vision for Hawaii